Calitate prin disciplină. Încredere prin transparență.

Ferdis nu s-a dezvoltat ca un brand lansat peste noapte, ci ca o evoluţie naturală a unei culturi industriale solide. Originile noastre se regăsesc în Top Profil Sistem (TPS), un actor cu tradiţie în metalurgie, profilare şi sisteme de protecţie – o bază care ne oferă astăzi compentenţa de a livra produse corecte, durabile şi fără compromis.

Într-o piaţă unde promisiunile se dau uşor şi se ţin greu, noi alegem să facem lucrurile simplu: să livrăm ce spunem şi să spunem ce lucrăm. Alegem materiale premium, tehnologii verificate şi procese controlate – pentru că lucrul bine realizat nu are nevoie de voci mari, ci de detalii corecte.

În toți acești ani, am învățat că metalul nu iartă superficialitatea.

Oțelul galvanizat, finisajele stabile și structurile robuste pe care le folosim nu sunt alegeri întâmplătoare — sunt concluziile trase din mii de metri de profilare, din lucrări montate în condiții diferite și din înțelegerea clară a ceea ce înseamnă durabilitatea în practică.

Oțel premium din Coreea de Sud

Folosim exclusiv oțel galvanizat Dongkuk Steel, unul dintre cei mai apreciați producători din Coreea de Sud, cu peste 60 de ani de experiență în materiale pentru construcții și industrie grea, recunoscuți pentru siderurgia inovatoare, ecologică și futuristă.

Oțelul este pregalvanizat în instalații complet automatizate, cu toleranțe stricte și acoperiri anticorozive uniforme, dezvoltate special pentru medii dificile.

Datorită acestor procese, materialul rezistă la condiții extreme, de la –50°C la +120°C, protejând eficient structura și păstrând culoarea în timp.

Un material stabil, verificat industrial

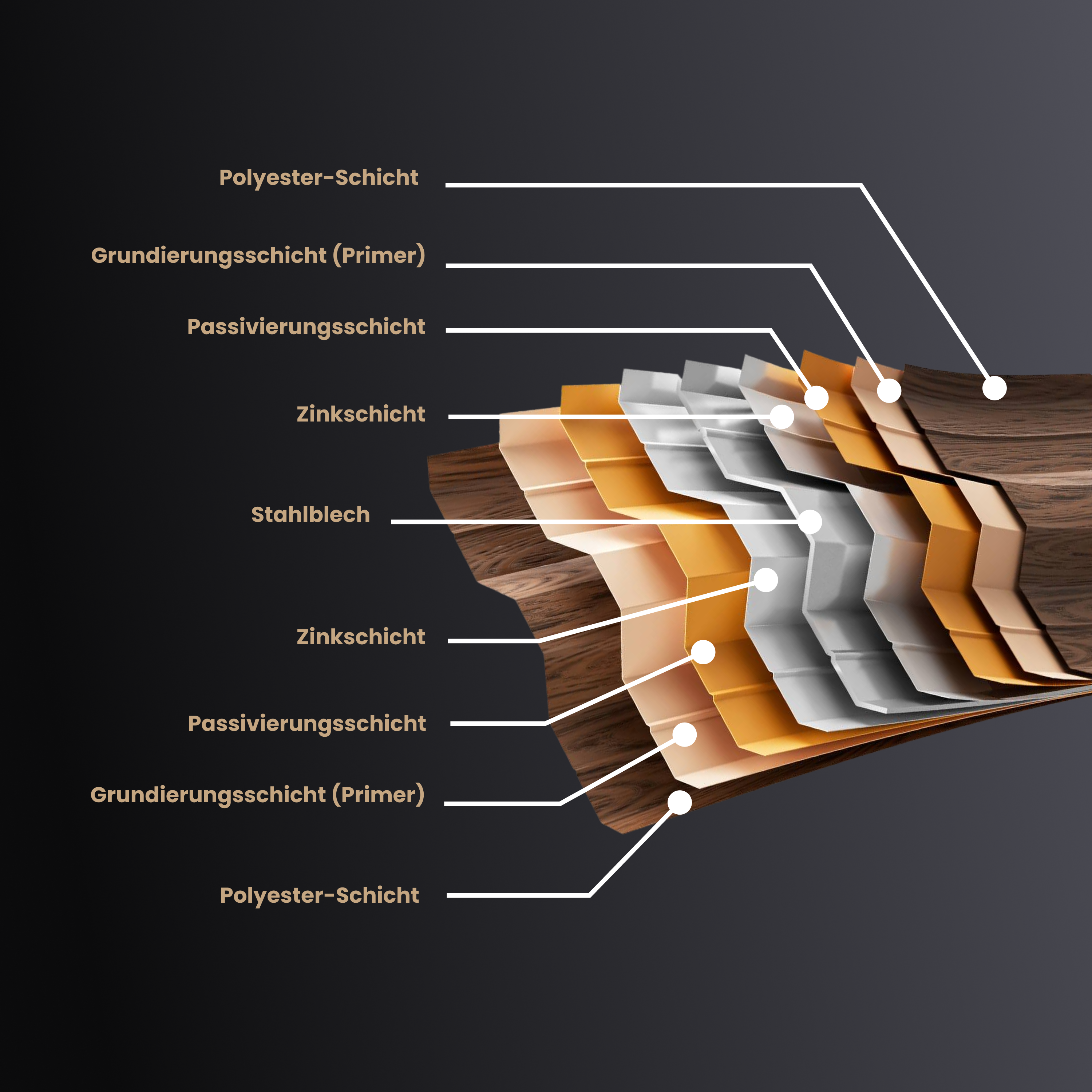

Struktur der Schutzschichten

Welche Schutzschichten hat das Metallprofil?

Stahlbleche mit niedrigem Kohlenstoffgehalt werden als Hauptrohstoff verwendet. Stahl, obwohl ein langlebiges Material, benötigt Schutz vor Korrosion. Um die Haltbarkeit zu gewährleisten, wird er auf beiden Seiten mit einer Zinkschicht überzogen. Auf den Stahl wird dann eine Passivierungsschicht und eine Grundierungsschicht aufgetragen. Der Prozess endet mit einer dekorativen Polymerschicht auf der Vorderseite und einer Schutzschicht auf der Rückseite.

Warum ist die Zinkschicht wichtig?

Die Anwendung einer Zinkschicht stellt sicher, dass die Stahlbasis nicht beschädigt wird, selbst wenn die äußeren Schichten des Metallprofils beschädigt sind.

Vorteile der Schutzschichten:

Dank dieser Schichten hält unser Metallprofil Bedingungen von -50°C bis +120°C stand, schützt den Stahl effektiv vor Korrosion und bewahrt die ursprüngliche Farbe.

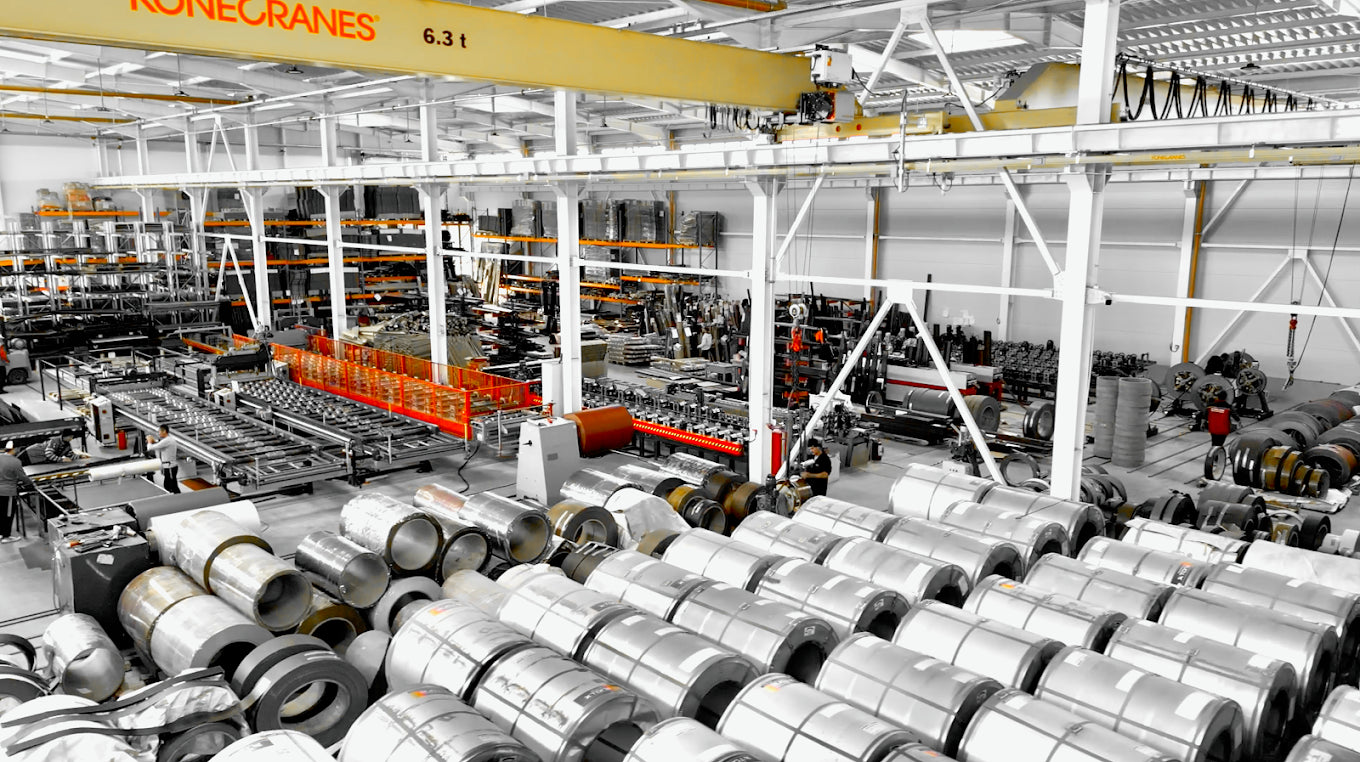

Automatisierte Produktion

Die vollständig automatisierte Produktion gewährleistet die höchste Produktqualität und geometrische Präzision durch den Einsatz modernster Technologien und hochmoderner Ausrüstung.

Farbstabilität

Unsere Zäune zeichnen sich durch ihre Lackbeständigkeit aus und bewahren die Sättigung und Tiefe der Farbe über viele Jahre hinweg. Selbst nach 15 Jahren bleibt die Farbe genauso strahlend und gesättigt wie am Tag des Kaufs.

Widerstand

Der Zaun wird Ihnen mehr als 50 Jahre dienen, dank seiner Basis aus feuerverzinktem Stahl mit niedrigen Kohlenstoffemissionen, die ihm korrosionsbeständige Eigenschaften verleiht. Er ist resistent gegen ultraviolette Strahlen und hält atmosphärischen Einflüssen sowie Temperaturen im Bereich von -50°C bis +120°C stand.

Hochwertige Materialien

Alle Produkte werden aus Materialien hergestellt, die von den Fabriken des südkoreanischen Unternehmens KG DONGBU STEEL geliefert werden - einem weltweit führenden Unternehmen im Bereich der Metallurgie.

Einfach zu montieren

Die intuitiven Anleitungen ermöglichen es Ihnen, den Zaun selbst ohne besondere Fähigkeiten zu montieren und zu installieren.

Minimaler Pflegeaufwand

Unsere Zäune sind so konzipiert, dass sie jahrzehntelang ohne zusätzliche Wartungskosten halten. Sie benötigen keine Neulackierung, Lackierung, Insektenschutzbehandlung, Schimmelbehandlung und Schutz vor anderen äußeren Einflüssen wie Sonnenlicht und Feuchtigkeit.

Breites Sortiment

Eine reiche Farbpalette, eine Vielzahl von Texturen und maßgefertigte Zäune garantieren die perfekte Komposition mit jeder Landschaft und jedem architektonischen Stil.

Transparență în loc de promisiuni

Nu pretindem că reinventăm industria. Dar ne asumăm ce controlăm:

- alegerea corectă a materiei prime,

- proiectarea precisă a sistemelor,

- simplitatea montajului,

- protecția anticorozivă,

- durabilitatea în timp.

Tot ce producem este gândit pentru a evita probleme pe care le vedem des în piață: panouri care se lasă, elemente care nu se aliniază, culori care nu rezistă, montaj care se transformă în reparat.

Reducem numărul de piese, stabilizăm structura, simplificăm instalarea.

Nu pentru că sună bine — ci pentru că reduce costuri și stres.

Fiecare gard este produs la comandă în fabrica noastră din Europa și livrat rapid – în mod obișnuit în intervalul de 5-7 zile. Echipa noastră este mereu disponibilă să-ți ofere informații și sprijin real, înainte, în timpul și întotdeauna după achiziție.

25 Jahre

für Metallzäune

30 Jahre

für Hi-mat und PRINT Zäune

15 Jahre

Ästhetische Garantie

Filosofia noastră este simplă

"Lucrurile bine făcute nu au nevoie de promisiuni mari.

Au nevoie de seriozitate, disciplină și responsabilitate.

Asta încercăm să livrăm în fiecare proiect."

Tu ai întrebări, noi avem răspunsuri

Nu ezita să ne contactați - echipa noastră va fi bucuroasă să te ajute!